The CO 2 can then be separated, and the hydrogen is used to generate power and/or heat. The carbon monoxide is subsequently converted to CO 2 in a ‘shift reactor’. Pre-combustion: The primary fuel in the process is reacted with steam and air or oxygen, and is converted to a mix of carbon monoxide and hydrogen, often called a ‘syngas’.This technology is particularly suited to retrofit applications (Parliamentary Office of Science & Technology, 2009). Typical applications for this technology include pulverized coal (PC) plants, and natural gas combined cycle plants (NGCC). Post-combustion separation involves the use of a solvent to capture the CO 2.

#CARBON CAPTURE AND STORAGE TECHNOLOGY FULL#

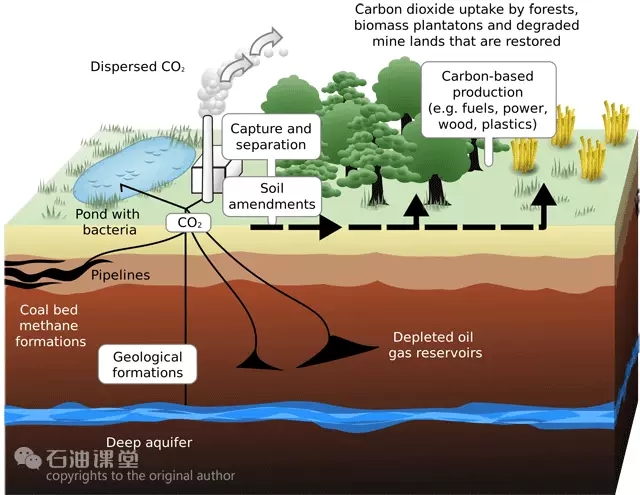

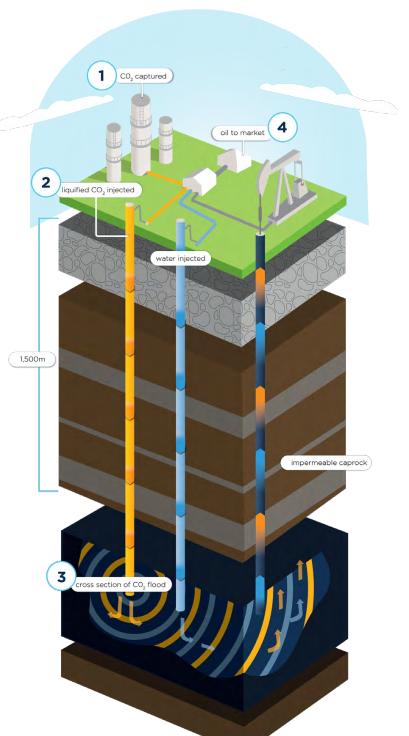

However, a full CCS chain has yet to be implemented, and many technical, environmental and economic uncertainties remain. The deployment of CCS in the industrial and power generation sectors would allow fossil fuel use to continue with a significant decrease in CO 2 emissions. The dominant reason to do CCS is CO 2 emission reductions from industry and power generation without incentives for such emission reductions, little CCS can be expected. Appropriate geological storage locations for CO 2 include abandoned oil and gas fields, deep saline formations and unminable coal seams. Feasible methods of transporting of CO 2 include both pipelines and shipping.

Basically, capture technology separates CO 2 emissions from the process, after which the compressed CO 2 is transported to a suitable geological storage location and injected. Carbon capture and storage (CCS) is a combination of technologies designed to prevent the release of CO 2 generated through conventional power generation and industrial production processes by injecting the CO 2 in suitable underground storage reservoirs.

0 kommentar(er)

0 kommentar(er)